DNV-Type Approval

Our core range holds DNV Type Approval to the DNV-ST-0378 standard, pre-approving our beams for use on DNV-classed offshore vessels and demanding marine projects worldwide.

BS EN 1090 Certification

We are accredited to BS EN 1090-2 Execution Class 3, ensuring our structural steel components meet the highest European manufacturing and quality control standards.

CE and UKCA Marking

Our Multisec products are fully certified and supplied with CE and UKCA marking, demonstrating total compliance with all relevant UK and European health, safety, and environmental protection legislation.

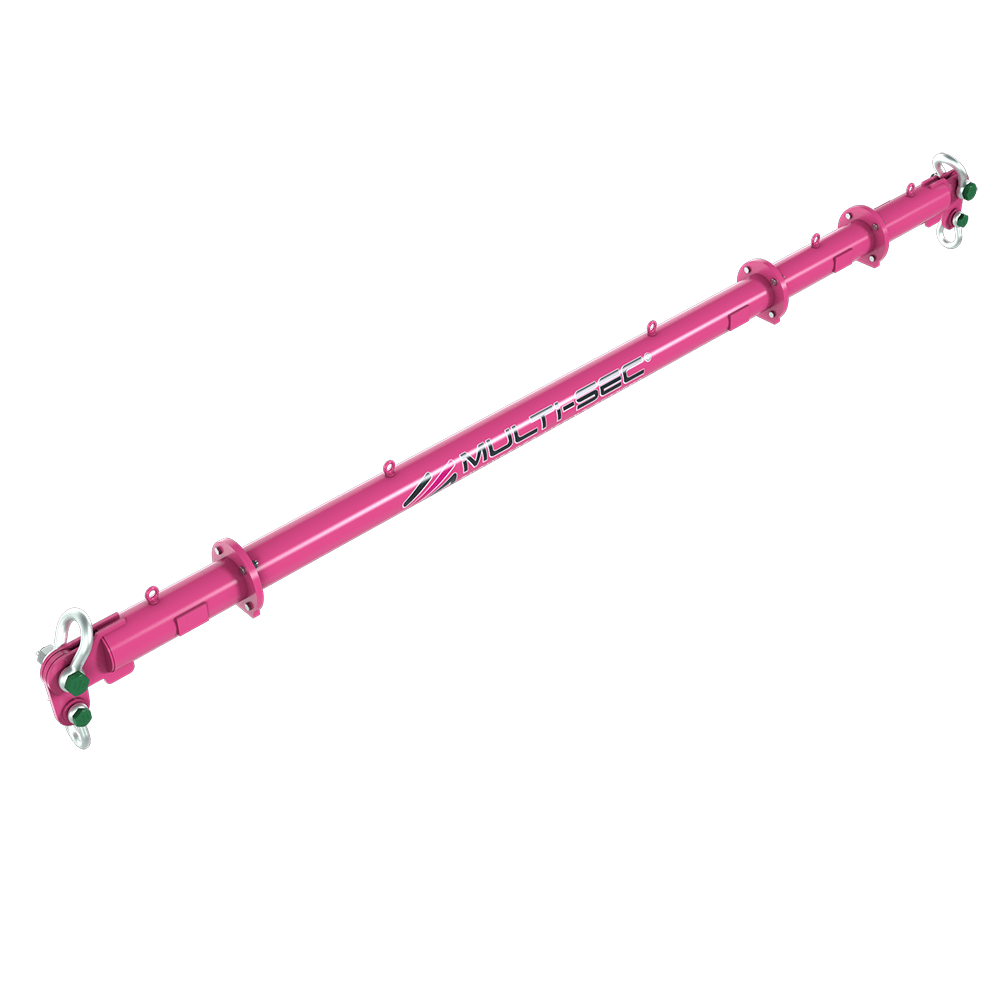

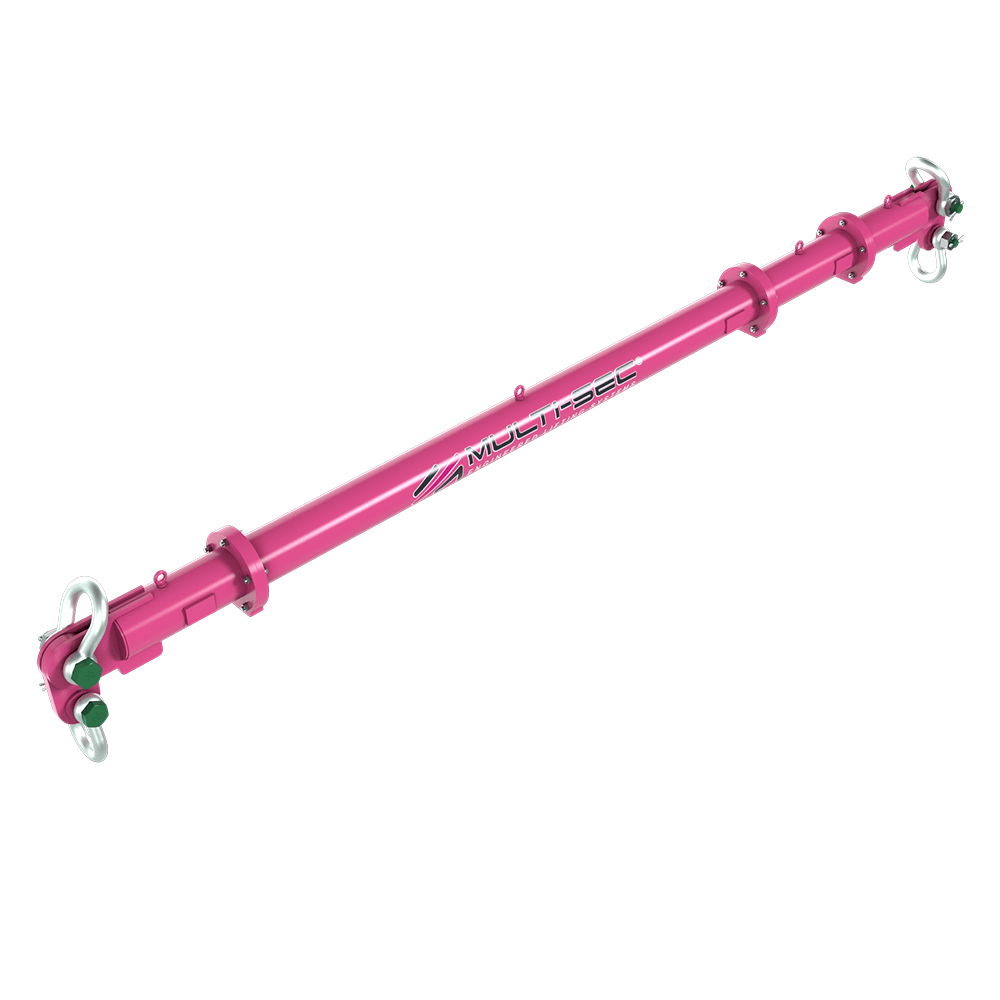

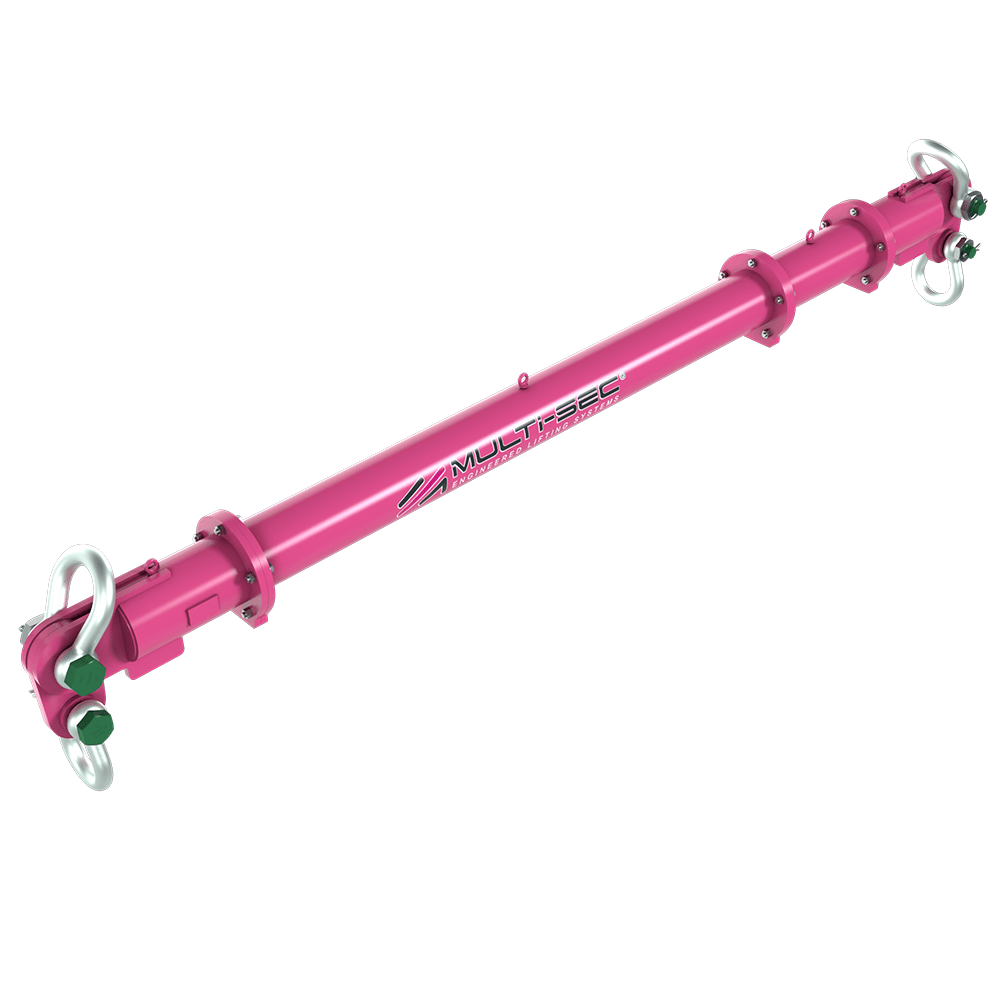

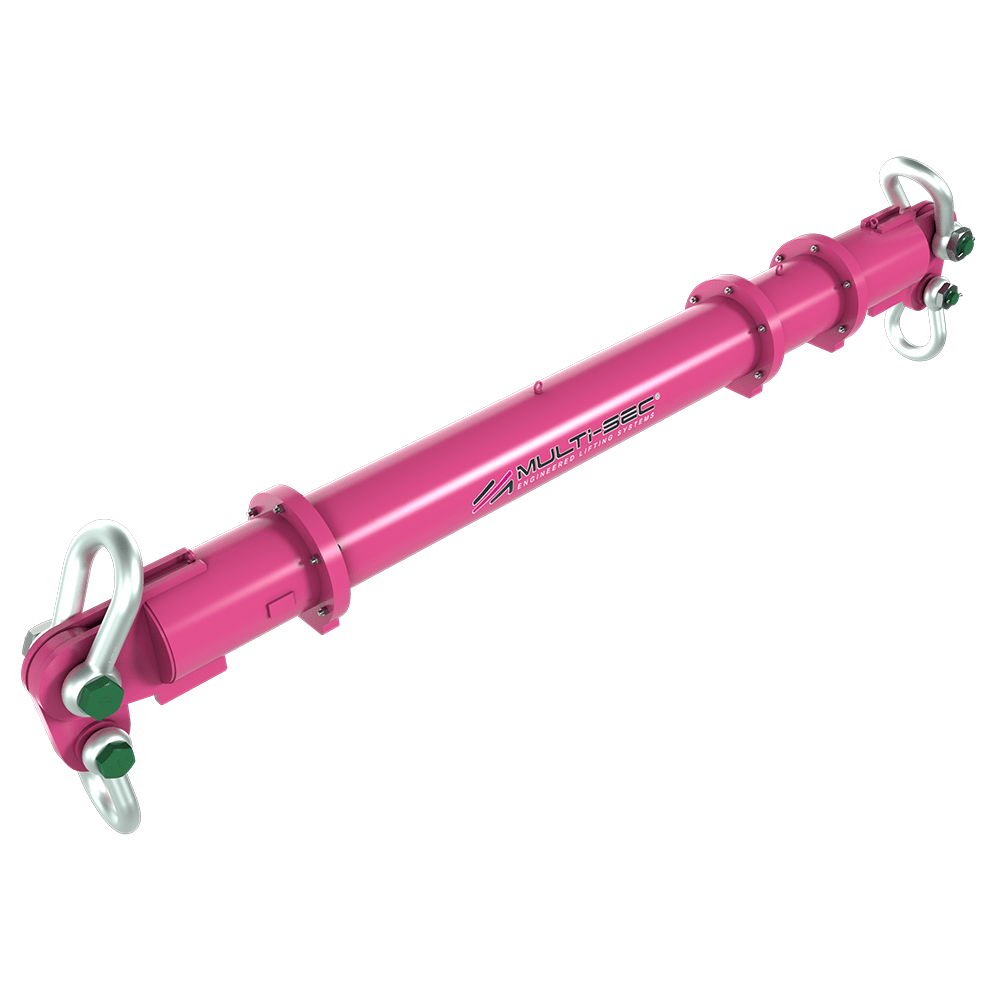

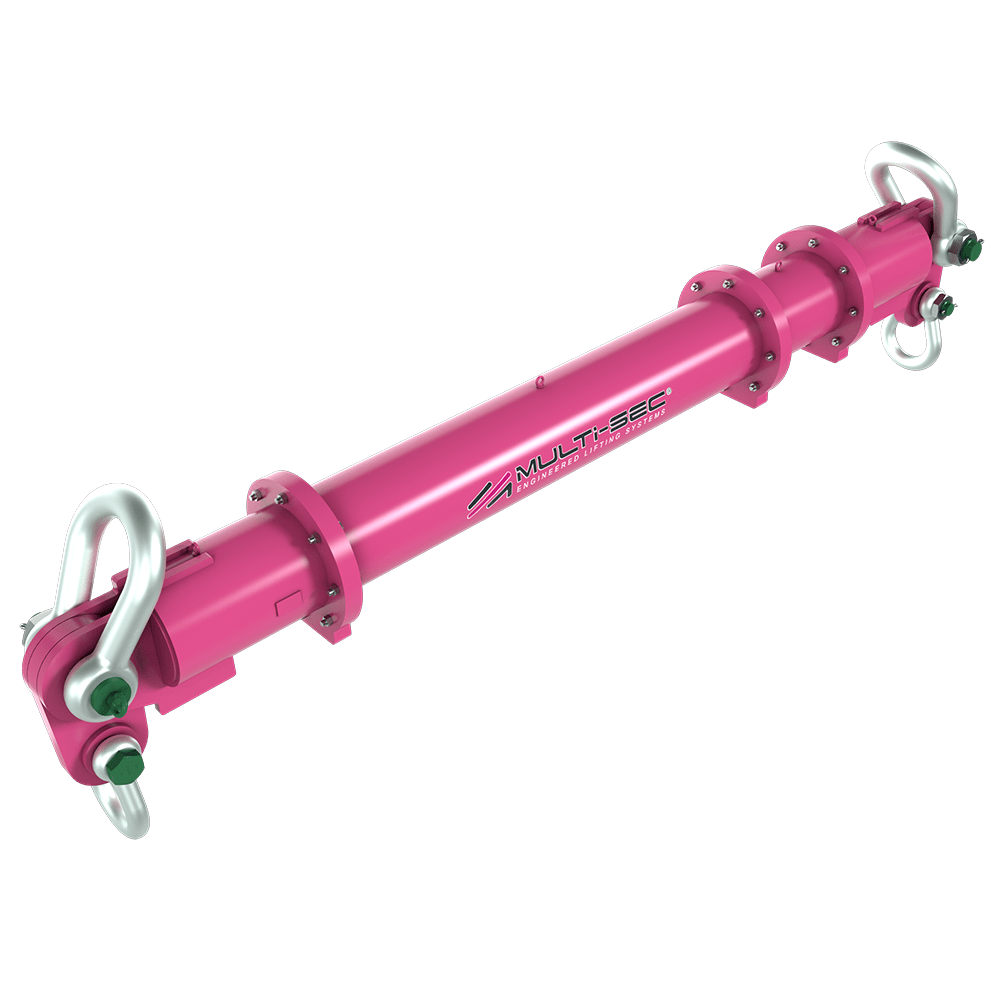

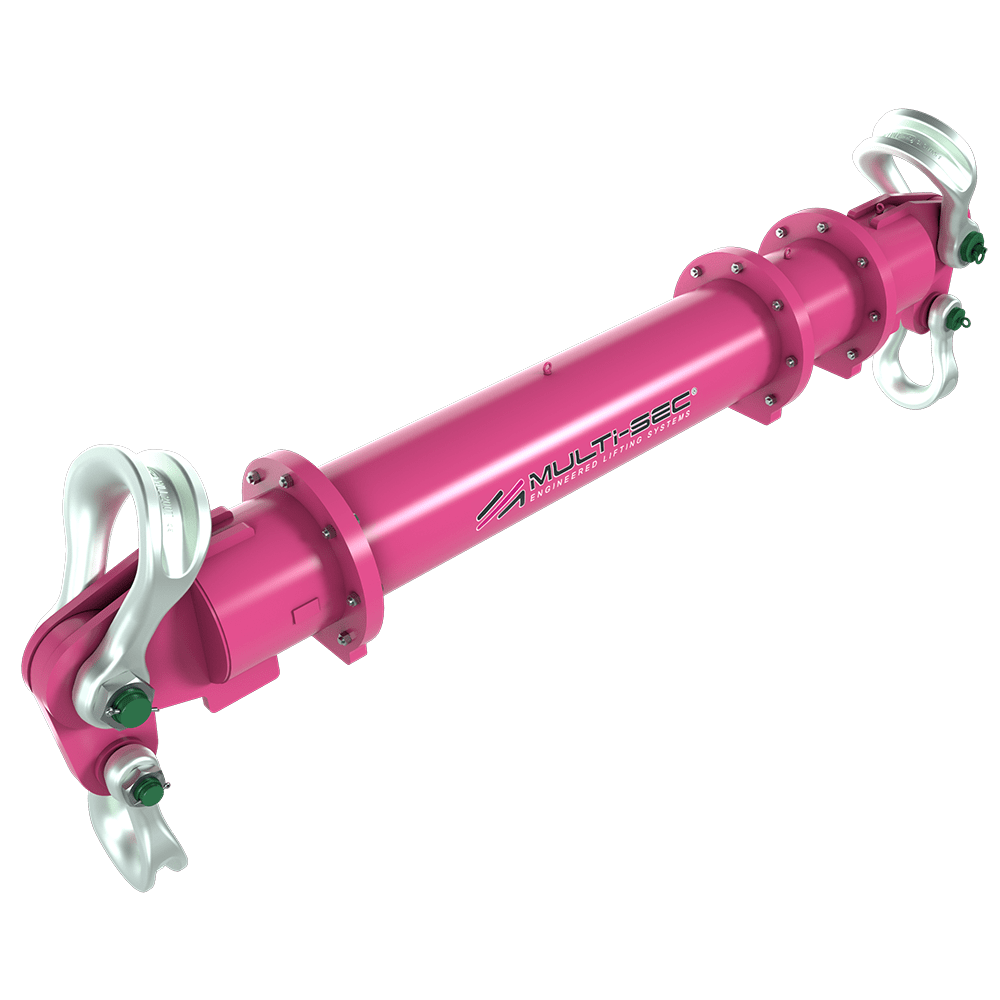

Multisec Modular Spreader Beams

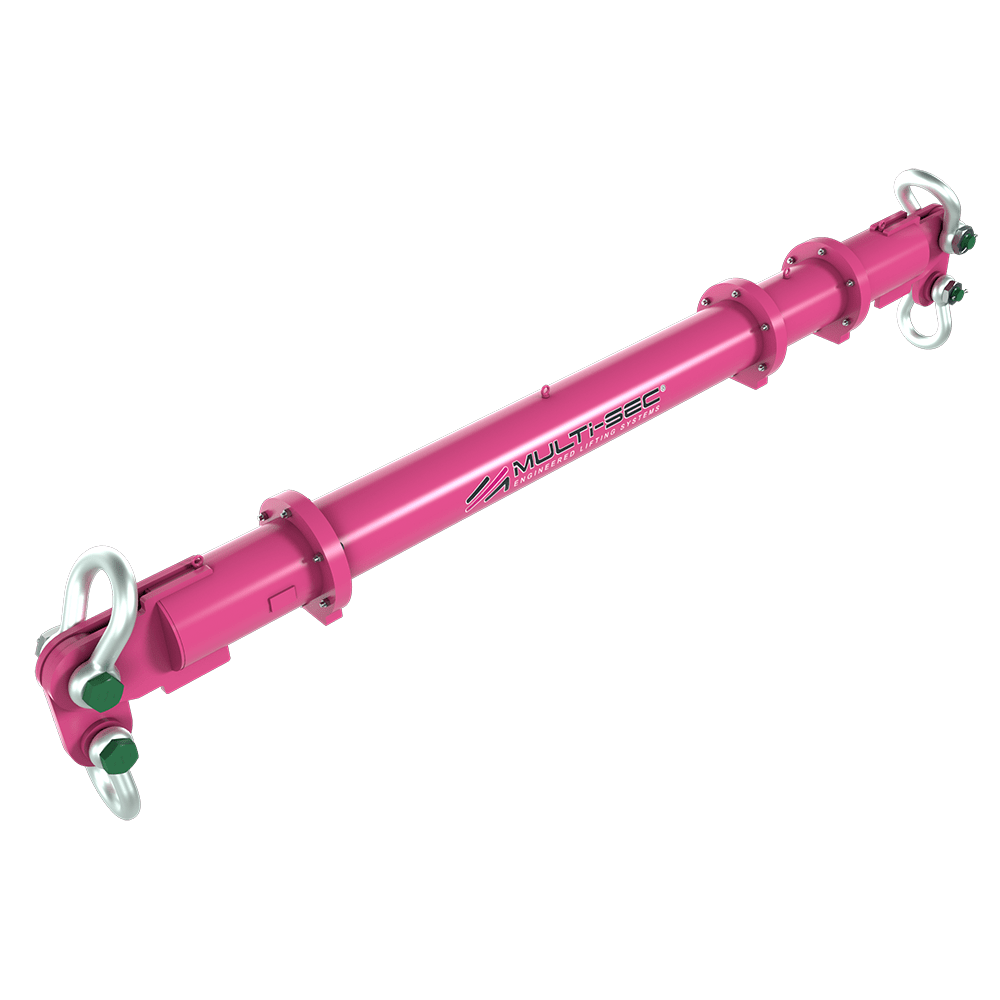

Multisec Modular Spreader Beams are DNV Type Approved lifting beams designed for the safe handling of heavy and oversized loads in onshore and offshore crane operations. Built from interchangeable struts and end units, the modular system can be configured in multiple lengths and lifting arrangements to suit specific project requirements.

DNV Type Approval independently confirms compliance with internationally recognised lifting standards, providing assurance of structural integrity, safety, and reliability in demanding environments. A single modular kit can be reconfigured for multiple lifts, reducing equipment costs while improving transport and storage efficiency through easily manageable components.

Widely used across offshore energy, construction, ports, and heavy engineering, Multisec Modular Spreader Beams deliver a certified, flexible, and cost-effective lifting solution.

Multisec Modular Spreader Beams in Action

Contact our sales team on for a quote and expert advice on the best lifting solution for your needs.

The Modular Spreader Beams Range

The modular design allows for effortless scaling. By selecting the appropriate end units and combining them with modular struts, you can achieve the precise span required for your lift. Select a model below to find the specific model required for your project capacity:

Can't find the size you need?

Contact Us for Custom & Bespoke Design solutions information

Get a Quote

Call our sales team on +44 (0)1642 240 672 or fill in the form below for a quote and expert advice on the best lifting solution for your needs.

Modular Spreader Beam FAQ

Modular spreader beams are commonly used for lifting and stabilizing heavy loads during overhead lifting operations. They are particularly useful when there is a need to maintain a load at or near a 90° angle, as they help distribute weight evenly and reduce stress on lifting slings.

Modular spreader beams are more versatile, lighter, and easier to transport compared to traditional lifting beams. They can be adjusted to different lengths on-site using basic tools, making them ideal for projects with varying lifting requirements. They also allow for easier storage and transport since they can be disassembled into smaller sections.

See our Spreader Beams Vs Lifting Beams for more information.

Our beams are designed for easy assembly with minimal tools. Simply connect the struts, end fittings, and bolts according to the load requirements. The process is straightforward, saving you time and reducing downtime on your projects.

Yes, one of the key benefits is their ability to be customised. They can be configured into different lengths and capacities by adding or removing sections. This makes them highly adaptable for different lifting scenarios.

Our expert team is here to assist you with any technical questions, assembly guidance, or support you may need. We also provide comprehensive documentation to ensure you get the most out of your spreader beam.

Safety is paramount when using modular spreader beams. Proper assembly, correct load distribution, and adherence to the manufacturer’s guidelines are critical. It’s also important to avoid misuse, such as adding additional lifting points in ways that could compromise the beam’s structural integrity.

Maintenance is simple and straightforward. Regular inspections for wear and tear, proper cleaning, and secure storage will keep your spreader beam in optimal condition. We recommend routine load testing to ensure ongoing safety and performance.

Multisec stands out for our durability, versatility, and ease of use. Our beams are engineered from high-strength steel, ensuring long-lasting performance under the toughest conditions. Plus, our modular design allows for flexible configurations, reducing the need for multiple specialised lifting devices, which saves you both time and money.