Modular Multi-Configuration System

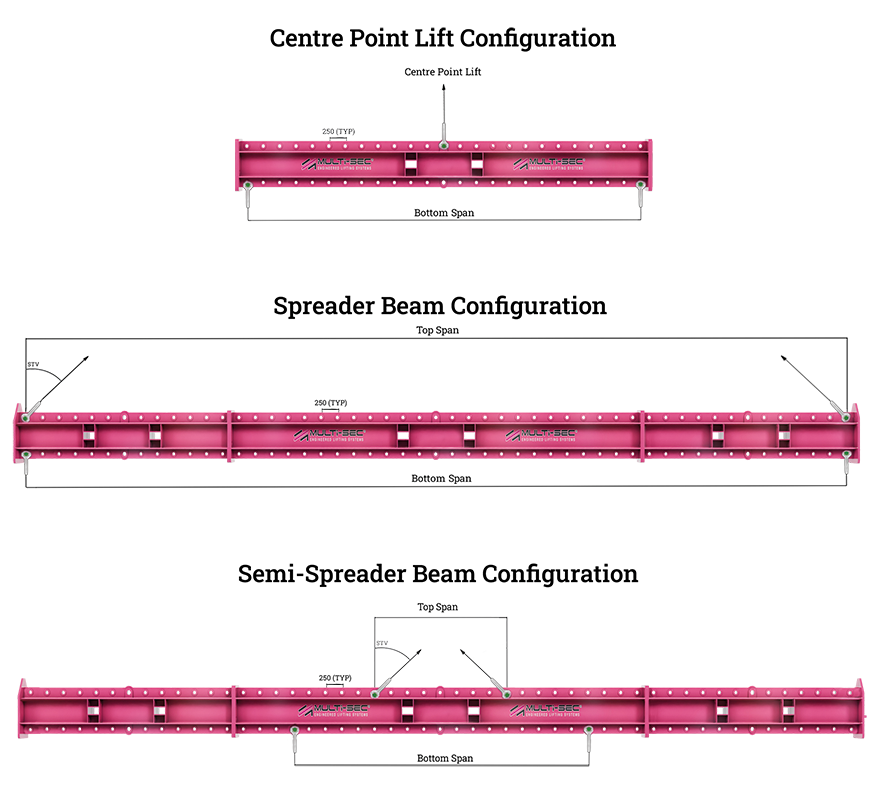

The Multi-Sec Multi-Point system is a reconfigurable modular solution that can be quickly assembled into Centre Point, Spreader, or Semi-Spreader configurations. This adaptability allows a single beam to handle everything from compact vertical lifts to complex, wide-span applications.

Multi-Lug Control & Load Distribution

Multiple lower lifting points allow loads to be supported at several positions for improved balance and controlled lifting. This is ideal for lifting long, flexible, or complex assemblies where load stability and accurate pick-point positioning are critical.

Heavy Duty Capacity with Practical Handling

Designed for demanding lifting operations, the MultiSec Multi-Point Lifting Beam range supports up to 300 tonnes with configurations up to 12m span, while integrated forklift pockets improve handling and positioning during mobilisation and site setup.

Multisec Multi-Point Lifting Beams

Multisec Multi-Point Lifting Beams are a modular, reconfigurable lifting system designed for multi-lug lifting, controlled load distribution, and complex rigging arrangements where a standard single-span beam is not enough.

Built for real lifting challenges, the Multisec range allows you to configure a single system for:

Centre point lifts

Spreader beam setups

Semi-spreader beam setups

With capacities up to 300 tonnes and spans up to 12 metres, Multisec provides a safe, adaptable and precise solution for both compact vertical lifts and multi-point lifting operations.

The Multi-Point Lifting Beams Range

The Multi-Point Lifting Beam is designed for controlled lifting from multiple lower lifting points with capacities up to 300T and spans up to 12 metres. The Multi-Lug beam can be configured as a centre point lift using 3m or 6m beam sections, or as a spreader or semi-spreader arrangement using 3m, 6m, 3m + 6m, or 3m + 6m + 3m beam combinations to suit requirements.

| Model | WLL | Max Span | Configurations |

| MP-13 | 13t | Up to 12m | Centre / Spreader / Semi |

| MP-25 | 25t | Up to 12m | Centre / Spreader / Semi |

| MP-34 | 34t | Up to 12m | Centre / Spreader / Semi |

| MP-50 | 50t | Up to 12m | Centre / Spreader / Semi |

| MP-100 | 100t | Up to 11.5m | Centre / Spreader / Semi |

| MP-300 | 300t | Up to 12m | Centre / Spreader / Semi |

Get a Quote

Call our sales team on +44 (0)1642 240 672 or fill in the form below for a quote and expert advice on the best lifting solution for your needs.

Frequently Asked Questions (FAQ)

A multi-point lifting beam is a lifting device with multiple load attachment points along the bottom beam. This allows loads to be lifted from several pick points simultaneously, improving stability and distributing forces evenly across the load.

There is no functional difference. Multi-lug lifting beam is an alternative industry term used to describe a multi-point lifting beam with multiple bottom lifting lugs to suit different load geometries.

MultiSec multi-point lifting beams are modular and are typically configured using 3 m and 6 m beam sections, allowing spans up to 12 metres, depending on model and configuration.

MultiSec multi-point lifting beams are modular and are typically configured using 3 m and 6 m beam sections, allowing spans up to 12 metres, depending on model and configuration.

Beam selection depends on the load weight, required span, lifting configuration, and site conditions. MultiSec provides technical support to ensure the correct beam is specified for each lift.