Maximize Efficiency

The Ultimate Guide to Modular Spreader Beams for Heavy Lifting

When it comes to heavy lifting, precision and efficiency are paramount. Enter modular spreader beams, the unsung heroes of safe and effective lifting solutions. Designed to withstand the demands of various loads while offering unparalleled versatility, these innovative tools enable operators to tackle complex lifting tasks with confidence. Whether you’re in construction, logistics, or manufacturing, understanding how to maximize efficiency with modular spreader beams can transform your operations. This ultimate guide delves into the key features, benefits, and applications of modular spreader beams, equipping you with the knowledge to optimize your lifting processes. By mastering these essential tools, you’ll not only enhance safety on site but also streamline your workflow and reduce downtime. Join us as we explore the world of modular spreader beams and discover how you can elevate your heavy lifting game to new heights.

Understanding the Importance of Heavy Lifting Equipment

Heavy lifting equipment is the backbone of modern industrial operations, enabling the movement of massive loads that would be impossible to handle manually. The essential role of this equipment spans various sectors, including construction, manufacturing, shipping, and logistics. Each industry relies on these robust tools to ensure that heavy materials are transported safely and efficiently, thus preventing operational delays and enhancing productivity.

In construction, heavy lifting equipment is crucial for moving large structural components, such as steel beams, pre-fabricated panels, and machinery, which are fundamental to building infrastructure. In manufacturing, these tools are indispensable for handling raw materials and finished products. Similarly, in logistics and shipping, lifting equipment is used to load and unload cargo, ensuring that goods are transported swiftly and securely. The precision and strength provided by these machines are unmatched, making them vital to the seamless operation of industrial activities.

The importance of heavy lifting equipment cannot be overstated, as it directly impacts the safety and efficiency of work environments. Poorly managed heavy lifting operations can lead to accidents, injuries, and significant financial losses. By utilizing the right equipment, companies can mitigate these risks and ensure compliance with safety regulations. This not only protects workers but also enhances the overall reliability and reputation of the business.

Modular spreader beams stand out as a versatile and efficient solution in the realm of heavy lifting. These beams are designed with a modular construction, allowing them to be configured in various lengths and capacities to meet the specific needs of a project. The primary feature of modular spreader beams is their adaptability, which enables operators to adjust the beam length by adding or removing sections, thereby accommodating different load sizes and weights.

Another critical feature is the ease of assembly and disassembly. Modular spreader beams are typically designed with user-friendly connectors and fasteners, making the setup process straightforward and time-efficient. This modularity not only saves time during installation but also simplifies transportation and storage, as disassembled components are easier to handle and move compared to large, fixed spreader beams.

Durability and strength are also paramount features of modular spreader beams. Constructed from high-grade materials, these beams are engineered to withstand the rigors of heavy lifting. They are subjected to rigorous testing and quality control to ensure they meet industry standards and can handle the specified load capacities without compromising safety. Additionally, many modular spreader beams come with features such as load monitoring systems and adjustable lifting points to further enhance their functionality and safety.

Benefits of Using Modular Spreader Beams in Heavy Lifting

The use of modular spreader beams in heavy lifting offers numerous benefits that can significantly enhance operational efficiency and safety. One of the primary advantages is the versatility these beams provide. Their modular design allows them to be easily reconfigured to suit different lifting requirements, making them a cost-effective solution for various projects. This flexibility means that a single set of modular spreader beams can be used for multiple applications, reducing the need to invest in multiple specialized lifting devices.

Another significant benefit is the improved safety that modular spreader beams offer. By distributing the load evenly across multiple points, these beams minimize the risk of load imbalance and potential accidents. Their robust construction ensures that they can handle the maximum specified load without bending or breaking, providing peace of mind to operators and site managers. Additionally, the ability to adjust the beam length means that lifting operations can be tailored to the specific dimensions of the load, further enhancing safety and stability.

Furthermore, modular spreader beams contribute to operational efficiency by reducing setup and dismantling times. The ease of assembly and disassembly means that lifting operations can commence more quickly, and equipment can be packed away promptly once the task is completed. This efficiency translates to reduced downtime and labor costs, allowing projects to stay on schedule and within budget. Overall, the use of modular spreader beams represents a smart investment for any industry involved in heavy lifting.

Choosing the right modular spreader beam for your project is crucial to ensure safe and efficient lifting operations. The selection process should begin with a thorough assessment of the specific lifting requirements, including the weight, size, and shape of the load to be lifted. Understanding these parameters will help determine the appropriate beam length, capacity, and configuration needed to handle the load safely.

Next, consider the environmental conditions in which the modular spreader beam will be used. Factors such as weather, temperature, and site accessibility can influence the choice of materials and design features. For instance, in corrosive environments or extreme temperatures, selecting beams made from corrosion-resistant materials or those with protective coatings can enhance durability and longevity. Additionally, the beam should be compatible with the lifting equipment available on site, such as cranes or hoists.

Lastly, it’s essential to evaluate the ease of assembly, disassembly, and transportation of the modular spreader beam. Opt for designs that offer user-friendly connectors and fasteners to streamline the setup process and reduce the potential for errors. Consider the storage and handling requirements, ensuring that the beam can be easily transported and stored when not in use. Consulting with manufacturers or suppliers who can provide expert guidance and support in selecting the right beam for your project can also be beneficial.

Installation and Setup of Modular Spreader Beams

Proper installation and setup of modular spreader beams are critical to ensuring safe and efficient lifting operations. The process begins with a detailed review of the manufacturer’s instructions and guidelines. These documents provide essential information on the correct assembly procedures, weight limits, and safety precautions that must be followed. It is important to ensure that all team members involved in the setup are familiar with these instructions to avoid any mistakes that could compromise safety.

Start by laying out all the components of the modular spreader beam in a clean, organized manner. Check each part for any signs of damage or wear and tear that could affect its performance. Assemble the beam according to the specified configuration, ensuring that all connections are secure and properly aligned. Use the appropriate tools and follow the recommended torque settings for fasteners to prevent over-tightening or under-tightening, which could weaken the assembly.

Once the beam is assembled, attach it to the lifting equipment, ensuring that all lifting points and slings are properly positioned and secured. Conduct a thorough pre-lift inspection to verify that everything is correctly set up and that there are no obstructions or hazards in the lifting area. Test the setup by performing a trial lift with a load slightly below the maximum capacity to ensure that the beam and lifting equipment are functioning correctly. If any issues are identified, address them immediately before proceeding with the full lift.

Safety Considerations When Using Spreader Beams

Safety is paramount when using spreader beams, as the improper handling of heavy loads can lead to serious accidents and injuries. One of the primary safety considerations is ensuring that the spreader beam is used within its specified load capacity. Overloading the beam can cause it to bend, break, or fail, posing significant risks to both personnel and equipment. It is essential to adhere strictly to the manufacturer’s guidelines and never exceed the rated capacity of the beam.

Another crucial safety aspect is the proper alignment and securement of the load. The load must be evenly distributed across the lifting points to prevent imbalance and sway during the lift. Using the correct type and length of slings, shackles, and other lifting accessories is vital to maintaining stability. Regularly inspect these components for signs of wear, damage, or deformation, and replace them if necessary to ensure they are in good working condition.

Conducting thorough risk assessments and implementing safety protocols are also key to preventing accidents. This includes identifying potential hazards in the lifting area, such as obstacles, overhead power lines, and uneven ground. Establishing clear communication channels between the lifting team members and using standardized hand signals or communication devices can help coordinate the lift effectively. Additionally, providing proper training and certification for operators and riggers ensures that they have the knowledge and skills to perform lifting tasks safely.

Maintenance Tips for Modular Spreader Beams

Regular maintenance is essential to keep modular spreader beams in optimal working condition and to extend their service life. Begin with a routine inspection schedule, which includes checking for signs of wear, corrosion, and damage. Inspect all components, including the beam sections, connectors, lifting points, and fasteners, to identify any issues that could affect performance. Pay particular attention to welds and joints, as these areas are prone to stress and fatigue.

Cleaning the spreader beam after each use is also important to prevent the buildup of dirt, grease, and other contaminants that can cause corrosion or interfere with the beam’s functionality. Use appropriate cleaning agents and methods based on the material of the beam, and ensure that all surfaces are thoroughly dried to prevent moisture-related damage. Store the beam in a dry, protected environment when not in use to minimize exposure to harsh conditions that could accelerate wear.

Additionally, follow the manufacturer’s recommendations for lubrication and tightening of fasteners. Regularly apply the specified lubricants to moving parts to reduce friction and wear. Check fasteners for proper torque settings and re-tighten as needed to maintain the integrity of the assembly. Keeping detailed records of maintenance activities, including inspections, repairs, and replacements, can help track the condition of the beam and ensure that it remains in safe working order.

Case Studies: Successful Applications of Modular Spreader Beams

Modular spreader beams have been successfully used in a variety of challenging lifting projects across different industries, showcasing their versatility and efficiency. In one notable case, a construction company utilized modular spreader beams to lift and position large steel girders for a bridge construction project. The beams’ adjustable length and capacity allowed the team to handle the varying sizes of girders, ensuring precise placement and stability throughout the operation. This flexibility helped the project stay on schedule and within budget, demonstrating the practical benefits of using modular spreader beams in complex construction tasks.

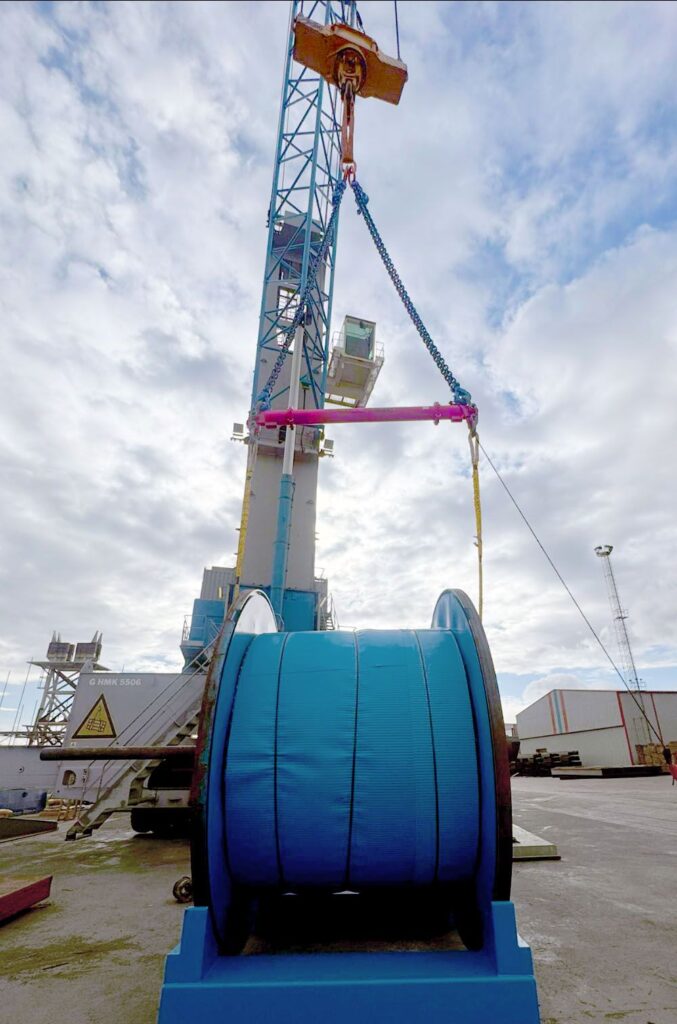

In the maritime industry, modular spreader beams have been employed to lift and transport heavy cargo containers in port operations. A major shipping company faced the challenge of handling oversized and irregularly shaped cargo that could not be managed with standard lifting equipment. By configuring modular spreader beams to match the dimensions of the cargo, the company was able to safely and efficiently load and unload the containers, minimizing the risk of damage and delays. The adaptability of the beams proved to be a valuable asset in optimizing port operations and enhancing cargo handling efficiency.

Another successful application was in the renewable energy sector, where modular spreader beams were used to install large wind turbine components. The beams’ ability to distribute the load evenly across multiple lifting points ensured the safe handling of delicate and heavy parts, such as turbine blades and nacelles. This precise control was crucial in preventing damage and ensuring the successful assembly of the turbines. The use of modular spreader beams in this context highlighted their importance in supporting the growth of sustainable energy projects by providing reliable and efficient lifting solutions.

Conclusion and Future Trends in Heavy Lifting Solutions

In conclusion, modular spreader beams represent a significant advancement in the field of heavy lifting, offering unparalleled versatility, safety, and efficiency. Their modular design allows them to be tailored to a wide range of lifting requirements, making them an invaluable tool for industries such as construction, manufacturing, logistics, and renewable energy. By understanding the key features, benefits, and proper usage of modular spreader beams, operators can optimize their lifting processes, enhance safety, and reduce downtime.

Looking ahead, the future of heavy lifting solutions is likely to see further innovations in modular spreader beam technology. Advancements in materials science could lead to the development of lighter, stronger, and more durable beams, while smart technology integration could enable real-time load monitoring and predictive maintenance. These innovations will continue to improve the efficiency and safety of lifting operations, providing even greater value to industries that rely on heavy lifting equipment.

As the demand for more sophisticated and adaptable lifting solutions grows, modular spreader beams will remain at the forefront of heavy lifting technology. Their proven track record in a variety of applications, combined with ongoing advancements, ensures that they will continue to play a vital role in supporting the safe and efficient handling of heavy loads. Embracing these tools and staying informed about the latest trends and best practices will help businesses stay competitive and achieve new heights in their lifting operations.