Multisec Products

Tri-Plates: Engineered Load Equalisation for Multi-Leg Lifting

Balanced load distribution in complex lifts

Tri-Plates provide a central connection point that promotes even load sharing across multiple slings, reducing stress concentrations on shackles, slings, and load points during multi-leg lifts.

Versatile for rigging, mooring & heavy lifting

Designed for rigging, lifting, towing, and mooring applications, Tri-Plates offer a compact and effective solution where conventional spreader systems may not be suitable.

Engineered for reliability and traceability

Manufactured with full material traceability and proof tested in-house, Tri-Plates deliver confidence in demanding marine, offshore, construction, and heavy lifting environments globally.

Multisec Tri-Plates

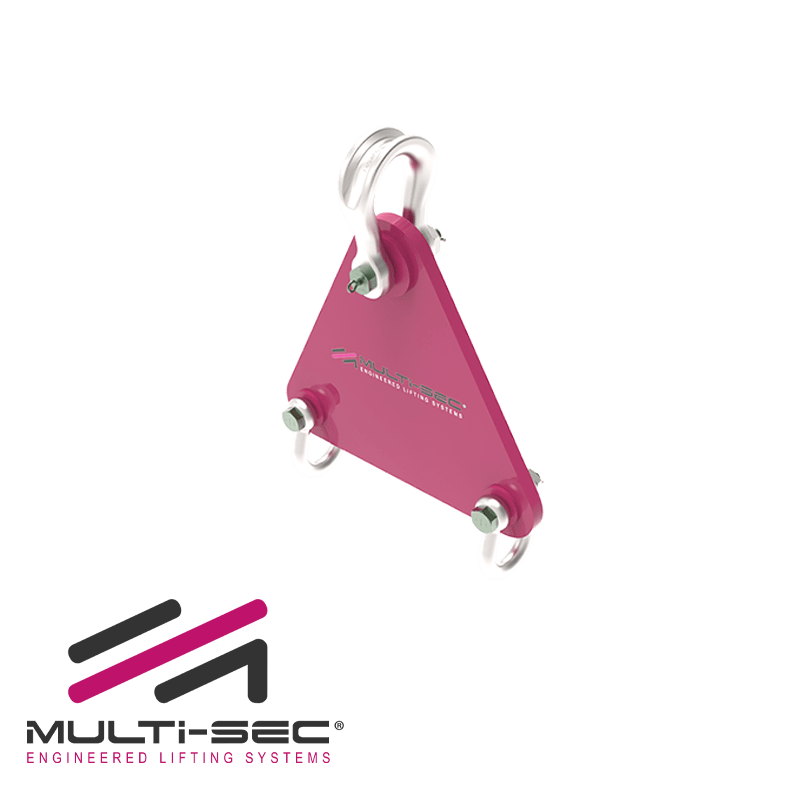

Multisec Tri-Plates (also commonly referred to as Triangle Plates, Delta Plates, or Monkey Plates) are engineered rigging components designed to provide efficient load distribution and controlled sling management in complex lifting arrangements. By creating a central connection point for multiple slings, Tri-Plates help reduce congestion at the lifting interface while promoting stable and balanced load transfer across the lift.

Key benefits include:

Centralised load equalisation for multi-leg lifting arrangements

Improved sling management and reduced bunching at connection points

Compact alternative where spreader beams are impractical

Suitable for demanding marine, offshore, construction, and heavy lifting applications

Manufactured with full material traceability and proof tested in-house, Multisec Tri-Plates provide a reliable and adaptable solution for critical lifting operations.

Typical Applications

Tri-Plates are widely used across industries where multiple slings converge and balanced load distribution is essential.

Construction & Civil Engineering

Used for rigging structural components and multi-leg lifts where load stability and sling management are priorities.

Offshore & Marine

Employed in subsea lifting, vessel mooring and towing setups to ensure even load transfer and reduced sling interference.

Oil & Gas Projects

Suit lifting and placement of heavy equipment in offshore and onshore installations where safety and reliability are paramount.

Industrial Heavy Lifting

Used in plant installation, maintenance, and bespoke lifting arrangements requiring precise force distribution.

Custom Project Rigging

Tri-Plates can be tailored to meet specific project requirements where standard lifting solutions are not adequate.

Technical Specifications

Tri-Plates Overview at a Glance

MultiSec Tri-Plates are supplied as engineered lifting accessories, configurable to meet project-specific requirements. Common specification considerations include:

Working Load Limit (WLL): Engineered for your application

Load connection points: Designed to suit the number and arrangement of sling legs

Material: High-strength steel with full traceability

Safety factor: In line with industry best practice (typically 5:1 or as required)

Testing: Proof load tested in-house prior to supply

Certification: Supplied with appropriate certification and documentation

Final configuration and capacities are confirmed during the quotation stage to ensure suitability for the intended lift.

Get a Quote

Multisec Tri-Plates are engineered to your project requirements. To provide a tailored quotation, complete the form below with as much detail as possible or Call our sales team on +44 (0)1642 240 672 for expert advice on the best solution for your needs.

Frequently Asked Questions (FAQ)

Tri-Plates are rigging accessories that provide a central connection point for multiple sling legs, promoting even load distribution and reducing sling interference. They are also known as Triangle Plates, Delta Plates, or Monkey Plates.

Tri-Plates are used in construction, rigging, marine/mooring, offshore, oil & gas, and heavy industrial lifting to manage complex, multi-leg loads safely.

By centralising sling connections and promoting balanced force transfer, Tri-Plates help reduce sling bunching and uneven load paths, increasing overall lift stability.

Yes. Multisec engineering can design bespoke Tri-Plates to meet specific project requirements that standard configurations cannot address.

Lifting points are positioned during configuration to suit the module geometry and structural pick-up points. The final arrangement is confirmed during the engineering and quotation stage.

Typically: load weight, module footprint and overall dimensions, lifting point locations, intended lifting method, and any headroom or site constraints. Providing drawings or a lifting plan can speed up the quotation process.