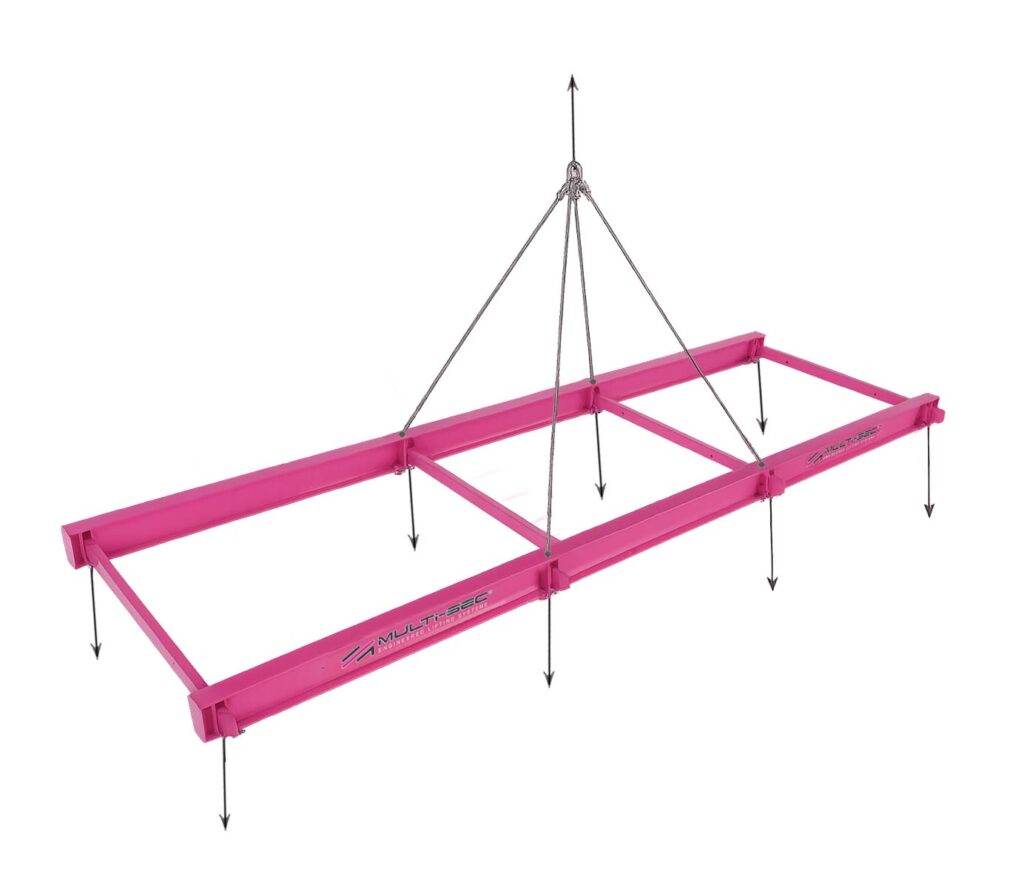

Adjustable Lifting Frames: Flexible Lifting for Modular & ISO Units

Adjustable to suit varying module footprints

Designed to accommodate changing load geometries, Adjustable Lifting Frames allow lifting points to be repositioned to suit different module sizes and layouts. This flexibility supports projects where multiple module designs are lifted using one frame system, reducing the need for multiple bespoke lifting solutions on site

Controlled load distribution for finished units

The adjustable lifting arrangement promotes balanced load transfer across the structure, helping to minimise localised stresses during lifting operations. This is particularly beneficial when handling finished modular units such as bathroom pods, where controlled lifting helps protect fixtures, surfaces, and structural integrity throughout repeated lifts safely.

Engineered for modular and ISO-format lifting

Adjustable Lifting Frames are engineered for modular construction and prefabricated units, commonly configured for ISO modules ranging from 20ft to 40ft. The adaptable frame geometry allows configuration to suit varying lifting interfaces and project requirements, while maintaining consistent lifting performance across different module types on site.

Multisec Adjustable Lifting Frames

Multisec Adjustable Lifting Frames provide a flexible lifting solution for modular buildings, bathroom pods, prefabricated units, and large structures with varying footprints. By allowing the lifting geometry to be configured to suit the load, these frames support safer and more efficient lifting across modular construction and offsite manufacturing projects.

Key benefits include:

Configurable lifting geometry to suit varying module sizes and layouts

Reduced requirement for multiple fixed lifting frames across a project

Consistent lifting approach for repeated modular units

Improved equipment utilisation and site efficiency

Each frame is engineered to suit the specific lifting requirement, ensuring compatibility with the module geometry and intended lifting method.

Typical Applications

Modular buildings

Used for volumetric modular construction where building units differ in size or layout across a project. Adjustable lifting geometry allows the same frame to be configured for multiple module designs, supporting efficient and repeatable lifting operations.

Common benefits:

Suitable for varying module footprints

Reduced need for multiple dedicated lifting frames

Consistent lifting approach across production or site installation

ISO-format modules (20ft–40ft)

Commonly configured for ISO-format modules where lifting point locations or interfaces vary between units, but a consistent lifting solution is required.

Common benefits:

Suitable for ISO modules typically ranging from 20ft to 40ft

Adjustable geometry to suit different module layouts

Efficient lifting across multiple ISO-format units

Bathroom Pods

Well suited to finished bathroom pods where controlled lifting is essential to protect internal fixtures and surface finishes. Even load distribution helps reduce the risk of damage during handling and installation.

Common benefits:

Balanced lifting to minimise localised stresses

Improved protection of tiles, fixtures, and finishes

Suitable for repeated pod installation programmes

Prefabricated units and large structures

Applicable to plant rooms, equipment skids, and prefabricated assemblies with non-uniform footprints or changing lifting requirements.

Common benefits:

Configurable lifting points to suit complex geometries

Adaptable solution for evolving project requirements

Suitable for controlled lifting of large prefabricated assemblies

Technical Specifications

Adjustable Lifting Frames Overview at a Glance

MultiSec Adjustable Lifting Frames are engineered to suit individual project requirements, allowing the lifting frame configuration to be matched precisely to the load geometry, lifting points, and intended application.

Typical specification parameters include:

Working Load Limit (WLL): Engineered to suit the application

Module size range: Commonly configured for ISO modules from 20ft to 40ft

Frame geometry: Adjustable length and width to suit varying footprints

Lifting point configuration: Adjustable to align with structural pick-up points

Connection methods: Slings or shackles, selected to suit the lifting arrangement

Application environment: Suitable for modular construction and prefabrication projects

Documentation: Supplied with a full certification and documentation pack

Final configuration, capacity, and lifting arrangement are confirmed during the engineering and quotation stage to ensure suitability for the specific lift.

Get a Quote

Call our sales team on +44 (0)1642 240 672 or fill in the form below for a quote and expert advice on the best lifting solution for your needs.

Frequently Asked Questions (FAQ)

An Adjustable Lifting Frame is a configurable lifting device designed to lift modular buildings, bathroom pods, and prefabricated units with varying footprints. The lifting geometry can be adjusted to suit the load, helping achieve stable lifting across different module sizes.

They are commonly used for modular buildings, bathroom pods, prefabricated units, and large structures with varying footprints, typically including ISO modules ranging from 20ft to 40ft.

Yes. Adjustable configurations are intended to support projects where module footprints and lifting point locations vary between lifts, reducing the need for multiple fixed lifting frames (subject to engineering review for each application).

By promoting balanced load transfer and aligning lifting points with structural pick-up locations, adjustable frames help minimise localised stresses during lifting—supporting safer handling of finished pods and prefabricated units.

Lifting points are positioned during configuration to suit the module geometry and structural pick-up points. The final arrangement is confirmed during the engineering and quotation stage.

Typically: load weight, module footprint and overall dimensions, lifting point locations, intended lifting method, and any headroom or site constraints. Providing drawings or a lifting plan can speed up the quotation process.

Yes. They are typically used for ISO modules ranging from 20ft to 40ft, where lifting interfaces and lifting point locations may vary between units.

Yes. Frames are supplied with a certification and documentation pack appropriate to the supplied lifting equipment and project requirements.

Yes. If you’re unsure what information to provide or how the lift should be arranged, you can speak to an engineer and we’ll help you identify the details required for an accurate quotation.