Multisec Modular Spreader Beam Buyer’s Guide

Discover the Ultimate Lifting Solution

What Is a Modular Spreader Beam?

The modular spreader beams are a versatile lifting system designed to safely handle heavy and oversized loads by distributing the weight evenly across two lifting points. Unlike fixed beams, Multisec Modular Spreader Beams are built from interchangeable struts and end fittings that can be configured in multiple lengths and capacities to suit the specific requirements of each lift.

This modular approach allows a single system to adapt to countless lifting scenarios — from shipbuilding and offshore wind installations to heavy manufacturing and infrastructure projects.

Every Multisec system is engineered, tested, and certified in the UK to meet the highest global lifting standards. Designed with durability, safety, and flexibility in mind, our beams deliver performance that endures even in the toughest environments.

Key Benefits:

Interchangeable Components – Adjust span and capacity easily using standard struts and end units.

High Load Range – Standard systems available from 13 tonnes up to 250 tonnes WLL.

Reduced Costs – One modular kit replaces multiple fixed beams, saving time and storage space.

Full Traceability – Every component is uniquely identified, CE-marked, and proof load tested.

Why Choose a Multisec Modular Spreader Beam?

How the System Works

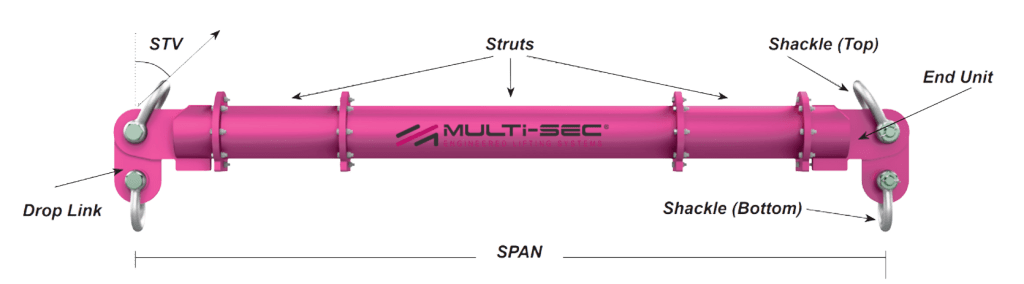

Each modular spreader beam consists of:

End Units – Connect the system to the top slings and load shackles.

Intermediate Struts – Bolted between the end units to set the required span.

Drop Links and Shackles – Transfer load safely from the beam to the lifting points.

By changing the combination of struts, you can create configurations for short, medium, or long spans — ideal for multi-project use.

Modular vs Fixed Spreader Beams

| Feature | Modular Spreader Beam | Fixed Spreader Beam |

|---|---|---|

| Span Flexibility | Adjustable via strut combinations | Fixed length |

| Transport & Storage | Compact and easily shipped | Bulky, single-use |

| Cost Efficiency | One system, many configurations | One beam per project |

| Maintenance | Replaceable parts | Full replacement needed |

How to Choose the Right Modular Spreader Beam

When selecting a modular beam, consider:

Load weight and dimensions

Available headroom

Center of gravity and rigging configuration

Lifting environment (onshore/offshore)

Our engineering team can help you design the safest, most efficient lifting configuration for your project.

Multisec Modular Spreader Beams are trusted across a range of sectors, including:

Offshore and Subsea Lifting

Wind Energy and Renewables

Shipbuilding and Marine Construction

Heavy Fabrication and Manufacturing

Infrastructure and Civil Engineering Projects

Each beam is designed to perform reliably in demanding conditions — from offshore decks to onshore lifting yards.

Real-World Performance

Applications Across Industries

Multisec beams have been used globally for:

Lifting offshore wind monopiles up to 1600 tonnes

Relocating marine pontoons and floating structures

Supporting complex four-point lifts using modular spreader frames

View our latest Projects for real examples of our systems in action.

Request a Quote or Build Your Configuration

Ready to configure your lifting system? Our experts can help you build the right Modular Spreader Beam Kit for your next project.